Have you ever wondered how the world of manufacturing has evolved in the blink of an eye? Welcome to the era of digital fabrication, where "desifake" is reshaping the game. This isn't just another buzzword; it's a revolution that’s transforming industries worldwide. Imagine a future where designs are created digitally and brought to life with precision, speed, and innovation. That’s exactly what desifake is all about. So, buckle up, because we’re diving deep into this fascinating world!

Digital fabrication—or desifake for short—is more than just a fancy term. It’s the backbone of modern manufacturing, blending cutting-edge technology with creative design. From 3D printing to CNC machining, the tools behind desifake are making waves across various sectors. Whether it’s aerospace, healthcare, or automotive, industries are embracing these advancements to stay competitive and efficient.

But here’s the real kicker: understanding desifake isn’t just for tech geeks or engineers anymore. It’s for anyone who wants to grasp the future of production. As we explore this topic, we’ll break it down into bite-sized pieces, so even if you’re not a tech wizard, you’ll leave with a solid understanding of how desifake is shaping the world around us. Let’s get started!

Read also:Fed Rate Decision What It Is Why It Matters And How It Affects You

Table of Contents

- What is Desifake?

- History of Digital Fabrication

- Key Technologies in Desifake

- Applications in Modern Industries

- Benefits and Challenges of Desifake

- Future Trends in Digital Fabrication

- Economic Impact of Desifake

- Environmental Considerations

- Skills Needed for Desifake

- Conclusion: Embracing the Desifake Revolution

What is Desifake?

Let’s kick things off with the basics. Desifake, short for digital fabrication, refers to the process of creating physical objects from digital designs using advanced machinery. Think of it as the ultimate merger of art and science. Unlike traditional manufacturing methods, which rely heavily on manual labor and analog tools, desifake leverages technology to streamline the production process.

In a nutshell, desifake involves using computer-aided design (CAD) software to create intricate blueprints, which are then translated into tangible products through machines like 3D printers, laser cutters, and CNC mills. This approach not only enhances precision but also reduces waste and production time. And hey, who doesn’t love efficiency?

But wait, there’s more! Desifake isn’t just about making things faster; it’s about pushing the boundaries of what’s possible. From custom prosthetics to complex aerospace components, the possibilities are endless. So, whether you’re designing a prototype or producing a final product, desifake has got your back.

History of Digital Fabrication

Desifake didn’t just pop up overnight. It’s been a gradual evolution, fueled by technological advancements and human ingenuity. The journey began in the 1970s with the development of CNC (Computer Numerical Control) machines, which allowed for automated cutting and shaping of materials.

Fast forward to the 1980s, and we saw the emergence of 3D printing, also known as additive manufacturing. This game-changing technology enabled the creation of three-dimensional objects layer by layer, revolutionizing the way we think about production. Over the years, advancements in software and hardware have only enhanced the capabilities of digital fabrication.

Key Milestones

- 1970s: Introduction of CNC machines

- 1980s: Birth of 3D printing

- 2000s: Widespread adoption across industries

- 2020s: Integration of AI and IoT in desifake processes

As you can see, the history of desifake is rich and full of milestones. Each step forward has paved the way for new possibilities, setting the stage for the innovations we see today.

Read also:Car Crash During Spring Break Our Lawyers Can Help

Key Technologies in Desifake

Now that we’ve covered the basics, let’s dive into the heart of desifake: the technologies that make it all possible. From 3D printing to robotics, these tools are the driving force behind the digital fabrication revolution.

3D Printing

Also known as additive manufacturing, 3D printing is one of the most popular technologies in desifake. It works by layering materials to create a three-dimensional object based on a digital design. The beauty of 3D printing lies in its versatility—it can be used with a wide range of materials, from plastics to metals.

CNC Machining

On the other end of the spectrum, we have CNC machining, which is a subtractive manufacturing process. Instead of adding layers, CNC machines remove material from a block to create the desired shape. This method is particularly useful for producing high-precision components.

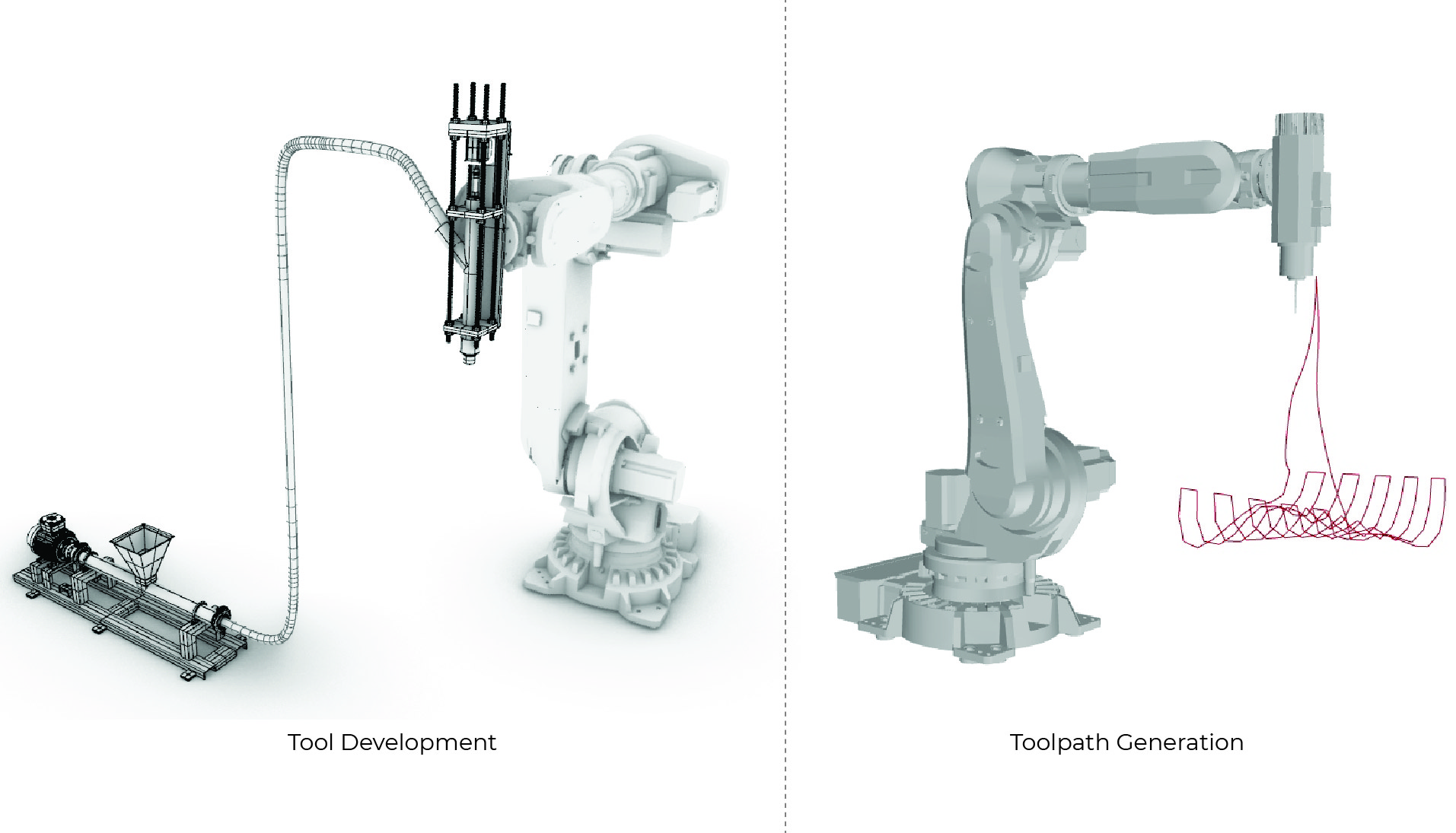

Robotics

Robotics plays a crucial role in desifake, especially in automating repetitive tasks. From assembly lines to quality control, robots are enhancing efficiency and accuracy in manufacturing processes.

These technologies, among others, are at the forefront of the desifake movement, each bringing its own set of advantages to the table. Together, they’re shaping the future of production as we know it.

Applications in Modern Industries

So, where exactly is desifake being used? The answer is simple: everywhere! From healthcare to aerospace, industries are finding innovative ways to incorporate digital fabrication into their workflows.

Healthcare

In the healthcare sector, desifake is making waves with the production of custom prosthetics, implants, and medical devices. Thanks to 3D printing, patients can now receive personalized solutions that fit their unique needs.

Aerospace

The aerospace industry is another major player in the desifake game. With the ability to produce lightweight and complex components, digital fabrication is helping companies reduce costs and improve performance.

Automotive

Over in the automotive world, desifake is streamlining the production of parts and prototypes. Manufacturers are using these technologies to create vehicles that are not only more efficient but also more sustainable.

These are just a few examples of how desifake is being applied across industries. As technology continues to evolve, we can expect to see even more groundbreaking applications in the years to come.

Benefits and Challenges of Desifake

While desifake offers numerous advantages, it’s not without its challenges. Let’s take a closer look at both sides of the coin.

Benefits

- Increased Efficiency: Desifake reduces production time and minimizes errors.

- Cost Savings: By eliminating waste and streamlining processes, companies can save money.

- Customization: Digital fabrication allows for personalized products tailored to individual needs.

Challenges

- High Initial Costs: Investing in desifake technologies can be expensive upfront.

- Skills Gap: There’s a growing need for workers with expertise in digital fabrication.

- Intellectual Property Concerns: The ease of replicating designs raises questions about copyright protection.

Despite these challenges, the benefits of desifake far outweigh the drawbacks. As industries adapt and innovate, many of these issues are likely to be resolved over time.

Future Trends in Digital Fabrication

Looking ahead, the future of desifake is bright. Emerging trends such as AI integration, IoT connectivity, and sustainable materials are set to further revolutionize the field. Here’s what we can expect:

AI and Machine Learning

Artificial intelligence and machine learning are being used to optimize desifake processes, from design to production. These technologies enable predictive maintenance, quality control, and real-time adjustments, enhancing overall efficiency.

IoT Integration

The Internet of Things (IoT) is connecting machines and systems, allowing for seamless communication and data exchange. This connectivity is improving productivity and enabling smarter decision-making in manufacturing environments.

Sustainable Materials

As environmental concerns grow, there’s a push towards using eco-friendly materials in desifake. From bioplastics to recycled metals, companies are exploring ways to reduce their carbon footprint while maintaining quality.

These trends highlight the exciting possibilities that lie ahead for digital fabrication. By embracing innovation, industries can continue to push the boundaries of what’s possible.

Economic Impact of Desifake

The economic implications of desifake are significant. As industries adopt these technologies, we’re seeing shifts in job markets, trade dynamics, and global competition. Here’s a closer look at the economic impact:

Job Creation

While some traditional manufacturing jobs may be replaced by automation, new roles are emerging in the field of digital fabrication. From CAD designers to machine operators, there’s a growing demand for skilled workers in this area.

Global Trade

Desifake is also changing the landscape of global trade. With the ability to produce locally, companies can reduce reliance on imports and exports, leading to more self-sufficient economies.

Competitive Advantage

Companies that embrace desifake gain a competitive edge in the market. By offering faster production times, lower costs, and customized products, they can capture a larger share of the consumer base.

The economic impact of desifake is multifaceted, influencing various aspects of the business world. As industries continue to adapt, the economic benefits are likely to become even more pronounced.

Environmental Considerations

As we discussed earlier, sustainability is a key concern in the world of desifake. With growing awareness of environmental issues, industries are under pressure to adopt greener practices. Here’s how desifake is addressing these challenges:

Reduced Waste

Unlike traditional manufacturing, which often generates significant waste, desifake minimizes material usage through precise production techniques. This reduction in waste is a major win for the environment.

Energy Efficiency

Modern desifake technologies are designed to be energy-efficient, consuming less power compared to older methods. This not only saves costs but also reduces the carbon footprint of manufacturing processes.

Recycled Materials

Using recycled materials in desifake is becoming increasingly common. This practice not only supports sustainability but also aligns with consumer demand for eco-friendly products.

By prioritizing environmental considerations, the desifake industry is setting a positive example for others to follow. As technology advances, we can expect to see even more sustainable solutions emerge.

Skills Needed for Desifake

As the demand for desifake grows, so does the need for skilled professionals in this field. Here’s a rundown of the skills required to thrive in the world of digital fabrication:

CAD Design

Proficiency in computer-aided design (CAD) software is essential for creating digital blueprints. Whether you’re designing a prototype or a final product, CAD skills are a must-have.

Programming

Understanding how to program machines is another critical skill. From coding CNC machines to operating 3D printers, knowledge of programming languages is invaluable in desifake.

Problem-Solving

Desifake often involves troubleshooting and finding creative solutions to challenges. Strong problem-solving skills are key to overcoming obstacles and improving processes.

By acquiring these skills, individuals can position themselves for success in the rapidly evolving field of digital fabrication.

Conclusion: Embracing the Desifake Revolution

And there you have it—a comprehensive look at understanding desifake and its impact on modern industries. From its history and key technologies to its applications and future trends, we’ve covered a lot of ground. But the most important takeaway is this: desifake isn’t just a trend; it’s a revolution that’s here to stay.

As industries continue to adopt